Technical

Help

& Education

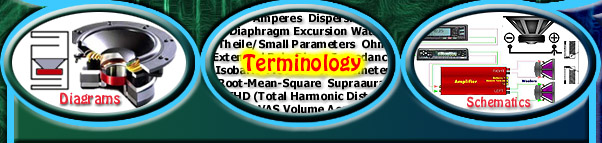

Glossary Of Terms

Speakers Main Page

How Speakers Work

Choosing Speakers

What's A Woofer?

What's A Midrange?

What's A Tweeter?

Other Speaker Types

More Speaker Types

What's A Capacitor?

Installing A Capacitor

What's A Crossover?

What's An Equalizer?

Speaker Enclosures

Theile/Small Param.

About Power Amps

Installing An Amp

Installation Tips

Power Ratings

Installing/Replacing

Head Units/Receivers

Installing Neon/LED

Eliminating Noise

Use The Right Tools

Manufacturer's

Links

Personal

& Marine

Electronics

Laptop Computers

Cell Phones & PDAs

Portable TV & Video

Electronic Readers

MP3/Music Players

CD

Players/Booms

Earphones/Buds

Digital Cameras

Video

Cameras

Personal GPS

Bluetooth

Calculators

Accessories

Marine

Electronics

Stereo Amplifiers

Stereo Speakers

Stereo Woofers

Enclosed Speakers

TVS & Video

CD/Mp3 Receivers

GPS & Navigation

Fish Finders

Accessories

Home

Stereo &

Office Electronics

Flat

Screen & HD TVs

Surround Sound

Home Theater

DVD Players/Tivo

DVD Recorders

Blu-Ray Devices

Amplifiers/Tuners

Speaker

Systems

Subwoofer Drivers

Midrange

Drivers

Tweeter Drivers

Powered Subwoofers

Outdoor

Speakers

Stereo Accessories

Digital

Photo Frames

Video Game Systems

Game

Accessories

Video Games

Home Security/Alarms

Computer

Products

Desktops & Laptops

Add-Ons/Peripherals

Computer Monitors

Computer Software

Computer Games

Printers &

Scanners

Ink/Specialty Papers

Parts & Components

Computer Supplies

Security/Tech

Support

Auto

Electronics

Amplifiers

Subwoofers

Full-Range Speakers

Midrange Speakers

Tweeters

Power Capacitors

Empty

Enclosures

Loaded Enclosures

CD/Mp3 Receivers

CD Changers

Bass Packages

Car

TV & Video

Satellite

Radio

Bluetooth Wireless

GPS Navigation

Neon/LED Lighting

Radar Detectors

Chrome

Mufflers

Car Alarms/Security

V

AUTO

PARTS STORE

Auto

Wiring &

Accessories

Air Horns

Power

Antennas

Antenna Boosters

A/V Controllers

Bass Blockers

Crossovers

Dynamat

Equalizers

Fans (Cooling)

FM Modulators

Interfaces

Line Converters

Noise Filters

Power Inverters

Power Supplies

RCA Cables

RCA Splitters

Remote Controls

Signal Boosters

Vibration Control

Speaker Grills

Wiring Kits

Speaker Boxes & Enclosures

Wondering what is meant by Sealed, Ported, Bass Reflex, Acoustic Suspension? These are all types of speaker enclosures or boxes, and all of these enclosure types are "direct radiator" enclosures. They are called this because the sound is produced directly from the "radiator" (the driver or speaker) without the assistance of a contrivance such as a horn. Other types such as, Bandpass, and Coupled Cavity enclosures are similar, but more complex.

Cardinal Rules for Enclosure Building

1. Build only for the internal volume size recommended by the woofer manufacturer.

2. Make the construction (sealed or ported) air-tight.

3. It is invariably more advantageous to buy, rather than build, both economically and to assure quality of construction. If you are an experienced cabinet maker with the proper tools, it will make a good project, otherwise....

Note, that enclosures exist solely for the purpose of accommodating the woofer. Tweeters and midranges do not have to be enclosed at all, though for the sake of convenience they are often mounted in enclosures along with the woofer. To help you decide which type is best for your purposes, we offer below some detailed explanations and illustrations of each type, along with information on the types of materials used in their construction and a few suggestions.

SEALED

BOX

The simplest direct-radiator system. The rear of the driver is in

a sealed enclosure, and none of the rear output of the driver contributes

to the sound output. Depending upon how stiff the mechanical suspension

is Vs how stiff the enclosed air in the enclosure is (and that's a function

of the size of the box), you can have one of two enclosure types: either

an Infinite Baffle enclosure, in which the mechanical suspension is

the dominant source of system stiffness and the box is large; or an

Acoustic Suspension enclosure, where the air in the box is the dominating

stiffness and the box is small. Sealed boxes tend to be among the lowest

efficiency systems for a given box size and bass cutoff frequency. They

are however quite good at reproducing a fairly broad range with little

deviation or distortion.

VENTED

ENCLOSURES

Also the same as Bass Reflex, Ported, or Passive Radiator. Here, an

aperture or port in the box provides a means for the rear output of

the cone to contribute to the total output of the system. However, it

only contributes over a very narrow range of frequencies. In fact, in

a properly designed system, the front output of the cone is reduced

at the same time the output of the port increases. Consequently the

port does not re-enforce the output of the woofer; it REPLACES the output

of the woofer at these frequencies. If done properly, this can significantly

reduce distortion and increase power handling at very low frequencies,

a region that can be difficult for drivers. A vented system can be up

to 3 dB more efficient at certain frequencies than a sealed box system

that has the same bass cutoff frequency and size.

BANDPASS

These are compound systems in that they have at least two enclosures:

one on the front and one on the rear of the driver. The enclosure on

the front, which looks remarkably like a vented box (because it is),

acts as a low pass filter and can couple the output of the woofer more

efficiently to the outside. They have several useful advantages. For

example, the front enclosure can be used as a very effective acoustic

crossover, filtering out mechanical noises generated by the woofer,

something no electronic crossover can do. For very low frequencies,

such an acoustic crossover can be far less expensive and more easily

designed than an equivalent electronic crossover. They are called "Bandpass"

because the combination of the rear enclosure and the driver form the

high pass portion while the front enclosure forms the low pass section.

Making the bandwidth of the system narrower raises the efficiency of

the system.

COUPLED

CAVITY

A variation of Bandpass and vented systems, the coupled cavity enclosure

is the result of attempts by designers to solve specific problems. These

enclosures consist of two or more rear enclosures, each coupled to the

next by a vent. Each enclosure/vent combination is another resonant

system, and the combination is, essentially, a high order, multi-tuned

resonant system. Generally, these systems have quite complex response

and are difficult to design. No comprehensive theory on their operation

exists like that for sealed, vented and Bandpass systems.

IMPEDANCE MATCHING IS IMPORTANT

Many builders and users like to take advantage of the power advantages of operating the amplifier in bridged or mono mode. To do so however, means that the impedance requirement of the drivers be taken into account when designing a proper circuit. For this purpose, we have provided an impedance calculator

MATERIALS

What is the best material to make speaker boxes? An ideal speaker cabinet

material would be very stiff, so that it would

tend to be stable with variations in box air pressure. It would also

be very well damped, so that if it ever does deflect from air pressure,

it will come back to the original position without resonating.

In addition, it would have a very high resonant frequency (supersonic),

so that low frequency box air pressure would not cause it to resonate.

An attractive material is preferred, and additional credit is given

for a material that is easy to cut, glue, and finish. A great material

would be cheap, too. Finally, it would be nice if the material were

light, because we all have to move our speakers sometimes, and it's

hard to appreciate good speakers with a sore back.

With

all of those attributes, it would seem that no material is perfect.

However, there are many materials that have enough of the above good

attributes to make excellent speaker cabinets. Each, however, has advantages

and disadvantages. In the list of good speaker box materials below,

the following code letters are used to indicate which attributes the

material possesses:

S

= Stiff -

D

= Damped -

H

= High Resonance

A

= Attractive -

M

= Malleable

C

= Cheap -

L

= Light.

MEDIUM

DENSITY FIBERBOARD (MDF)

Code:

SDMC

This is the most practical material for quality speaker enclosures.

It's extremely rigid and resistant to sympathetic vibrations in thicknesses

over half an inch. It cuts very nicely and has a smooth surface. It

takes veneer very well. However, bring a helper when you pick the stuff

up; one sheet is very heavy. MDF is harder on tools than common wood,

but easier than particle board. This is the material that many great

speaker makers use. Approximately $45 for a 4'x8'x1" sheet. Density:

50-lbs./Cu. ft.

POLYCARBONATE

(LEXAN)

Code:

DMA

A clear or solid-color polycarbonate box can look strikingly good. However,

this is not a cheap material. To locate it, look in the classified directory

under PLASTICS. Approximately $400 for a 4'x8'x0.5" sheet. Density:

75-lbs./Cu. ft. Acrylic (Plexiglas) is cheaper than Polycarbonate, but

weaker and not as well damped (not recommended as a main construction

material, but used for "windows" in Bandpass enclosures).

PLYWOOD

SPACED AND FILLED WITH SAND OR LEAD SHOT

Code:

SDAMC

Not a good choice for Car stereo because of weight issues.

If you have time on your hands and want a great impractical box, try

this. Make a simple box out of common plywood. Then glue cleats on the

outside of the box to space the outside plywood from the common plywood.

Glue hardwood-veneered plywood to the cleats and pour sand or lead shot

into the spaces between the cleats. It won't be light, but with the

filler, it will be extremely well damped. In addition, if you use strong

cleats and glue well, the box will be extremely stiff. One designer

was known to use different size Sonotubes as an alternative to plywood,

and filled the space between them with sand. Be sure to sterilize the

sand in your oven before putting it in the box.

ALUMINUM

SHEETS FILLED WITH ALUMINUM HONEYCOMB (Aerolam)

Code:

SDHL

Airplanes use this material for flooring. Next time a plane crashes

in your neighborhood, see if you can get the wreckage for your next

speaker project. You can't get a better, lightweight material. If you're

really ambitious, you can make your own sandwich out of high-quality

plywood faces and a thick honeycomb core. You will probably need an

epoxy to glue the honeycomb to the plywood. A home-brew sandwich is

easier to cut and glue than Aerolam.

FORMED

CONCRETE

Code:

SDHC

Not a good choice for car speakers due to weight. There are tricks to

working concrete, such as to cast braces, rebar, and steel-wire right

into the mix. Also, some types of concrete are better damped than others.

Remember to oil your concrete forms so that they can be removed. Most

concrete speakers use an MDF front panel, but you can pour one if you

use cardboard tubes or plywood rings to mold the concrete into the shape

of a speaker cutout.

Alternately, you can make a common veneered plywood speaker box and cast concrete inside it for stiffening. Any box can be improved by making the walls thicker, by bracing the walls, and by stiffening the walls. The stiffness of a material goes up as the cube of the thickness, so a slightly thicker material is much stiffer. A thicker panel will also have a higher resonant frequency because the stiffness goes up faster than the mass. Consider lining the inside of your speaker with ceramic tile, attached with thinset mortar. You can get tile remnants cheaply. They are easy to apply and can be added as an afterthought to an imperfect box. However, be sure to attach all braces before tiling, because it is hard to attach anything to tile. Also consider bracing any weak parts of the box. For example, all joints will benefit from a wooden cleat. The back of the box will benefit from stiffeners where the speaker terminals are attached. Most importantly, brace the front panel, or make it out of a double thickness of material.

For

a great deal more particular information along with interactive calculators

on speaker construction see:

Articles at the

Best Car Electronics

Theory Site

MAIN

PAGE

GLOSSARY

SPEAKERS:

Choosing

General

Woofers

Miidrange

Tweeters

Full-Range

Full-Range 2

CAPACITORS

CROSSOVERS

EQUALIZERS

Theile/Small

AMPLIFIERS:

About

Installing

Install Tips

Power Ratings

RECEIVERS:

Installing

NEON/LED:

Installing

TOOLS

Home

--

Policies

--

Products

--

Tech

Center

--

Auto

Electronics

--

Home

Electronics

--

Personal

& Marine Electronics

--

Stereo

Tech Info

Website Designed & Maintained by

MetroDirect

Communications

Copyright (c) 2000 - 2009

Electronixwarehouse.com

.

Use of any material appearing on this site without specific written

permission is prohibitied by law.

electronixwarehouse.com

---

logobannerfactory.com

---

bleepthem.com (Political Satire)

---

rlebeaux.com

---

stereotechnicalinformation.com (Stereo

Technical Help)

---

electronixwarehouse.net

---

thespeakerstore.com

---

wmpublishing.com (Help For Writers)

---

barbarathenovel.com

---

cutethenovel.com